Properties of dolomite

The chemical composition of dolomite is CaMg(CO3)2, and the crystals belong to trigonal carbonate minerals. The crystal structure of dolomite is similar to that of calcite, the crystal shape is rhombohedral, and the crystal surface is often curved into a saddle shape. Pure white marble is white, because it contains other elements and impurities sometimes gray green, gray yellow, pink and other colors, glass luster. Three groups of rhombohedral cleavage complete, brittle. mosh hardness 3.5~4, specific gravity 2.8~2.9. Mineral powder reacts slowly in cold diluted hydrochloric acid.

Dolomite Grinding Mill

Dolomite after selection, crushing, grinding 325 ~ 2000 mesh into dolomite powder, with the dolomite powder industry scale and application requirements upgrade, the traditional small-scale, multi-equipment extensive processing mode can not meet the market demand, therefore, the use of new powder technology equipment to improve the processing scale and technical level of enterprises is urgent. CLUM series ultra-fine vertical mill is a comprehensive mill with six functions, such as crushing, drying, grading, transportation, secondary powder selection and finished product packaging, which has been developed by Clirik for many years. It can effectively improve the added value of dolomite products, and the output of CLUM series ultra-fine vertical mill can be increased by 30%.  Ultrafine Vertical Roller Mill

Ultrafine Vertical Roller Mill

Capacity:1 ~ 20 t/h

Feeding size:< 20 mm

Powder fineness:300 ~ 3000 mesh

Mill Advantages1. Wide range of applications

CLUM series ultra-fine vertical roller mill can not only process dolomite, but also process and grind calcium carbonate, talc, magnesium oxide, magnesium hydroxide, aluminum hydroxide, magnesium carbonate, calcium carbonate, limestone, gypsum powder, carbon black and other materials.

2. Adjust freely

CLUM series ultra-fine vertical roller mill can freely change the fineness of the powder to be processed in the range of 300 mesh to 3000 mesh.

3. High production capacity

Our optimized CLUM series of ultrafine vertical roller grinders, grinding wheel, flow guide system, internal circulation system, ensure the grinding efficiency of the grinding equipment, compared with the traditional grinding equipment production 10-20%.

4. Low operating cost

CLUM series ultrafine vertical roller mill grading wheel is made of wear-resistant material, and after heat treatment process, long service life.The wearing parts of grinding wheels and disks are made of wear-resistant alloys to ensure a long service life under severe wear conditions in the field of barite and talc processing, reducing the replacement cost of wearing parts and minimizing the user's maintenance downtime.

5. Smart

CLUM series ultrafine vertical roller mill adopts PLC control and touch screen operation to realize automatic operation of vertical mill production line, and can display and save real-time operation data such as speed, temperature, pressure and pressure difference.

Dolomite Application

The dolomite powder processed by ultra-fine vertical grinding machine can be filled in natural rubber and synthetic rubber, and its rubber performance is basically the same as that of light calcium powder, but the cost is lower than that of light calcium powder. The use of dolomite to produce rubber universal calcium magnesium powder, as a new filler and colorant, can partially or completely replace the light calcium powder. The surface modification of dolomite powder can greatly increase the reinforcing properties of rubber products. The modified dolomite powder is coated with surface modifier and then used as filler. Commonly used surface modifiers are stearic acid or stearate, titanate, zirconium aluminate, mixed silane coupling agent and so on. The purpose of modification is to change the surface alkalinity of dolomite powder, overcome the bonding property between filler and rubber, reduce shrinkage and internal stress, prevent crack diffusion, and improve the processing property of product strength.

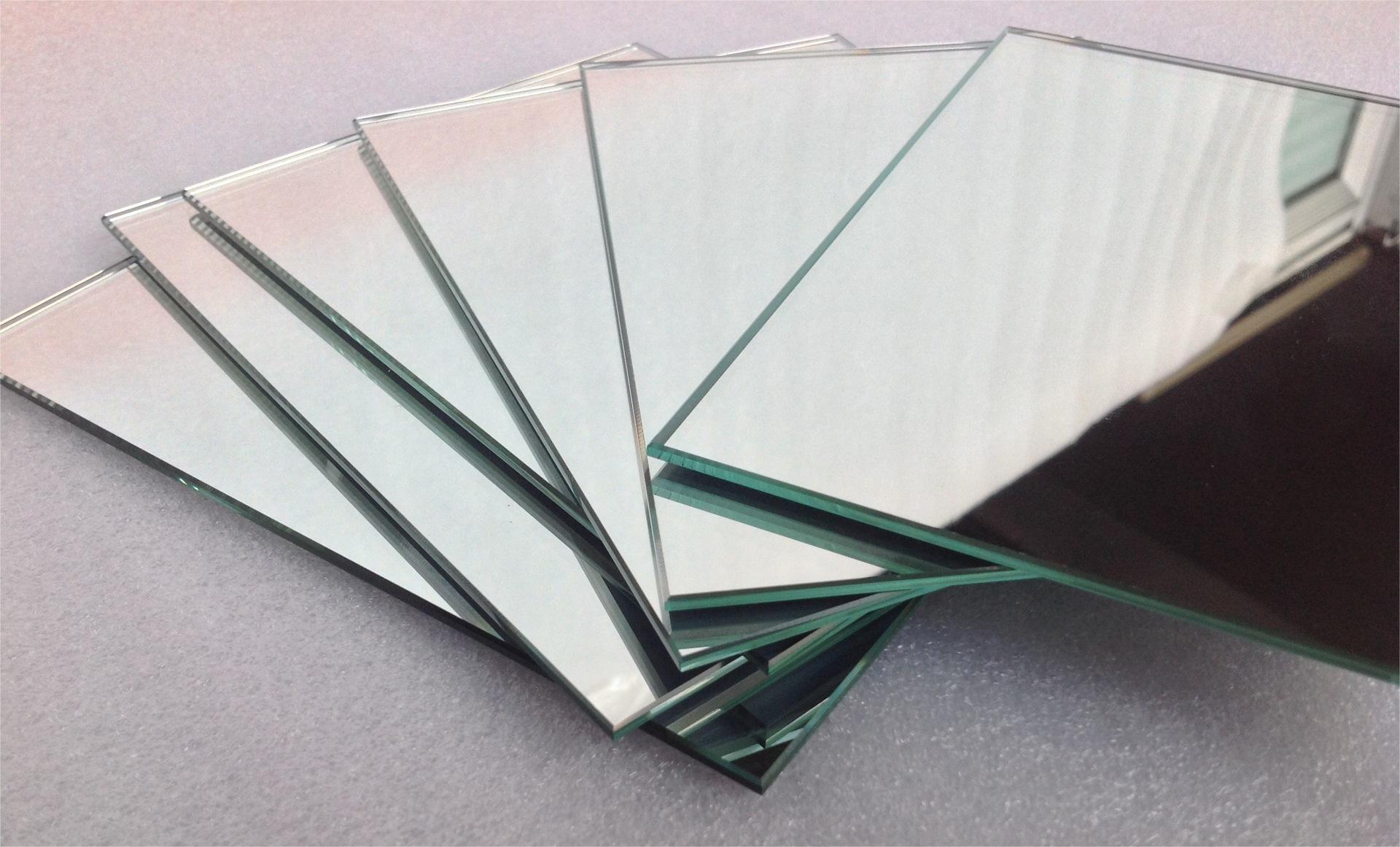

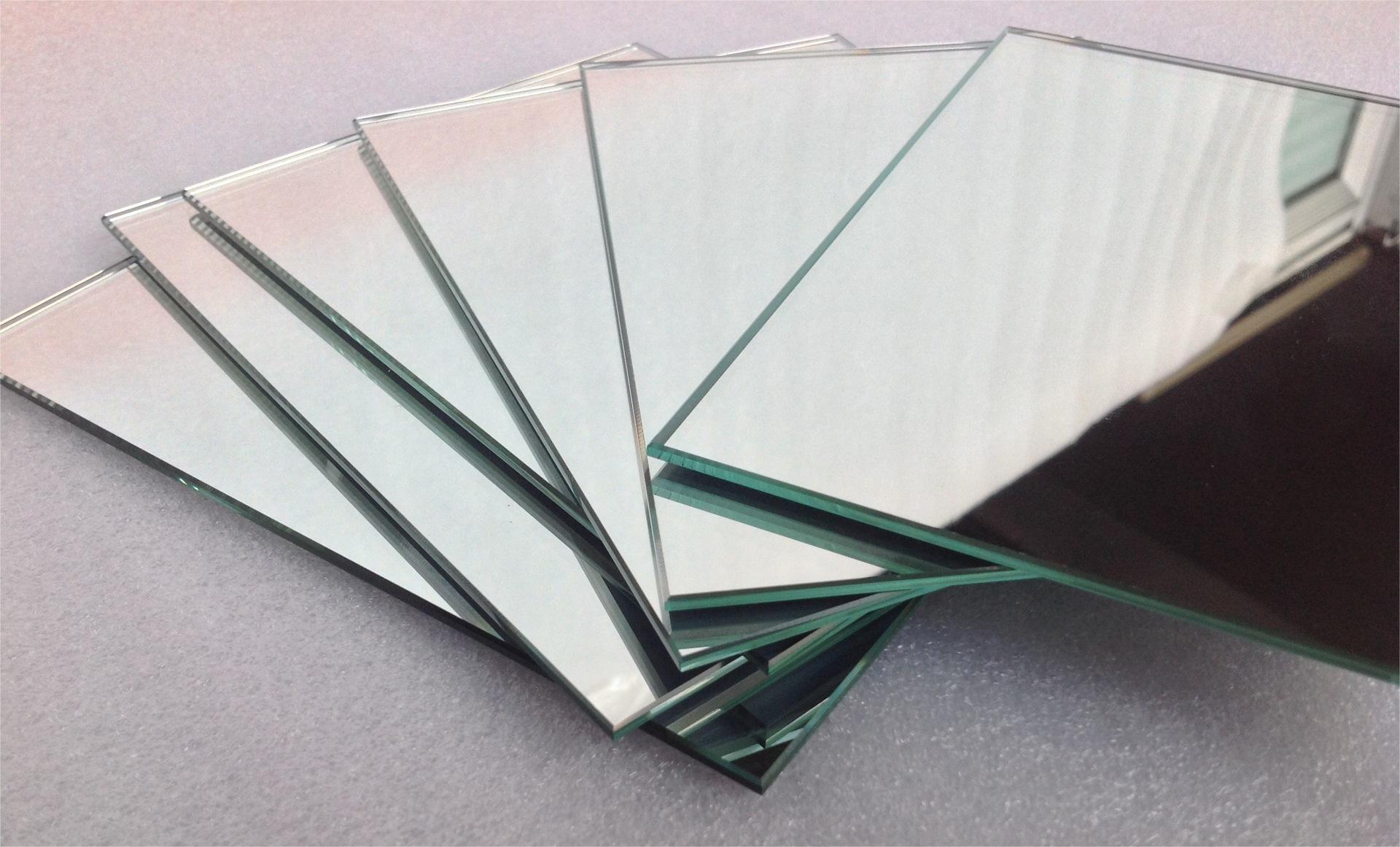

- Use in Glass Products

Dolomite and limestone are the third major components of glass raw materials besides silica sand and soda powder. In the production of bottle glass, soda powder is the most expensive component, adding limestone can partially replace soda powder, but it will have adverse effects, and the introduction of magnesia in dolomite can further reduce costs. Dolomite in the glass industry can also provide calcium oxide, adding soda ash - gray - silica system, play the role of flux. In addition, dolomite can also reduce glass aging, prevent chemical erosion caused by atmosphere or water, improve the plasticity of colored glass, and improve the strength of glass. Adding a certain amount of dolomite powder can effectively reduce the high-temperature viscosity of glass and improve the chemical stability and mechanical strength of the product. The practice also shows that the energy consumption can be significantly saved by using dolomite powder in the preparation of low-temperature ceramics and float glass ingredients.

Dolomite and limestone are the third major components of glass raw materials besides silica sand and soda powder. In the production of bottle glass, soda powder is the most expensive component, adding limestone can partially replace soda powder, but it will have adverse effects, and the introduction of magnesia in dolomite can further reduce costs. Dolomite in the glass industry can also provide calcium oxide, adding soda ash - gray - silica system, play the role of flux. In addition, dolomite can also reduce glass aging, prevent chemical erosion caused by atmosphere or water, improve the plasticity of colored glass, and improve the strength of glass. Adding a certain amount of dolomite powder can effectively reduce the high-temperature viscosity of glass and improve the chemical stability and mechanical strength of the product. The practice also shows that the energy consumption can be significantly saved by using dolomite powder in the preparation of low-temperature ceramics and float glass ingredients.

- Use in Metallurgical Industry

Magnesium smelting industry: Dolomite with raw ore size of 30 ~ 120mm is an important raw material for the production of metal magnesium, and its smelting method is mainly divided into two categories, namely, electrolysis and silicothermal reduction.

Magnesium smelting industry: Dolomite with raw ore size of 30 ~ 120mm is an important raw material for the production of metal magnesium, and its smelting method is mainly divided into two categories, namely, electrolysis and silicothermal reduction.

Refractory: Dolomite as one of the important raw materials of basic refractory materials, its importance is second only to magnesite, mainly used in steelmaking converter lining, open furnace furnace, electric furnace furnace wall, followed by the furnace refining equipment and cement kiln and other thermal equipment. Dolomite can produce dolomite brick series (at present, there are mainly conventional dolomite brick, zirconium dolomite brick, zirconium magnesia dolomite brick, etc.), electromelting dolomite carbon brick and electromelting magnesia dolomite carbon brick.

- Use in Building Materials

The manufacture of magnesium-oxychloride cement is another important use of dolomite. This magnesium-containing cement has good compressive, flexural strength and corrosion resistance. In particular, the magnesium oxychloride cement prepared by using the caustic powder prepared by flame-proof forging dolomite has better stability. Mg-containing cement has been widely used in the repair of floor plates, fast solidifying pavement and pavement cracks. In addition, after calcining dolomite to produce caustic dolomite, it can also be processed into magnesium hydroxide cement and magnesium oxide sulfate cement. These two kinds of non-hydraulic cementing materials have the advantages of simple production process, fast setting and hardening, high strength, strong bonding force, good elasticity, wear resistance, convenient forming, low energy consumption, etc., and have high development and use value.Clirik is a professional manufacturer of mining machinery and equipment, the production of machinery and equipment in the world are very popular, if you are interested in our equipment, please contact us through the contact information on the page, we also have professional engineering and technical personnel for you to customize machinery and equipment, to meet your requirements, to create suitable for your use of equipment, welcome your call!

sales@clirik.com

sales@clirik.com +86-21-20236178 86-13917147829

+86-21-20236178 86-13917147829

sales@clirik.com

sales@clirik.com +86-21-20236178 86-13917147829

+86-21-20236178 86-13917147829